It is very important for any person involved in the manufacturing or assembling of electronic products to get training from an IPC certified institute. Whether you are working for the automotive, aerospace, military, telecommunications, appliances or industrial equipment industry, IPC certification can play a key role in shaping your career. IPC is well known for its commitment to keep evolving standards of excellence to benefit enterprises that manufacture, specify, use, and design printed circuit boards and assemblies. IPC is a leading certifying body of quality in the electronics industry. It has contributed to an estimated $2.17 trillion electronics industry since the beginning of its journey in 1957. Since then, IPC has grown into an organization which regulates the standards of over 3,500 member companies worldwide.

Here are three of the most significant reasons denoting why you should get training with IPC certification:

- The standards of IPC are the epitome of the ideal practices within the electronics industry. An IPC certification gives that stamp of success to your resume.

- Cross-channel communication is a vital aspect of consistent and acceptable standards of quality in the electronics industry; IPC certification smoothly allows communication in the same language.

- An IPC certification makes you capable of delivering the needs of the electronics industry.

A.R.T Ltd, an IPC accredited training partner, provides a plethora of IPC training courses for professionals associated with the electronics industry. Here are few highlights of training courses that’s been offered by A.R.T Ltd.

- IPC-A-610: This course of training is designed specifically for trainers and quality supervisors versed in electronics assembly with inspection responsibilities in engineering and manufacturing.

- IPC-J-STD-001: Following course can be proven crucial for those in industry who are looking to pursue a career in the process and acceptance criteria for electrical and electronic assemblies. This training course prescribes material requirements, process requirements, and acceptability requirements for the manufacture of soldered electrical and electronic assemblies.

- IPC 7711/7721: Technicians, manufacturing and quality assurance supervisors are strongly encouraged to earn this endorsement, who need to develop skills required to restore operation of expensive electronics assemblies. However, candidates should have prior knowledge and experience in rework and repair of circuit boards as this training course is of an advanced level.

- IPC/WHMA-A-620: Following endorsement is designed for assembly process engineers, quality assurance supervisors, training managers and others responsible for the quality and reliability of cable and wire harness assemblies.

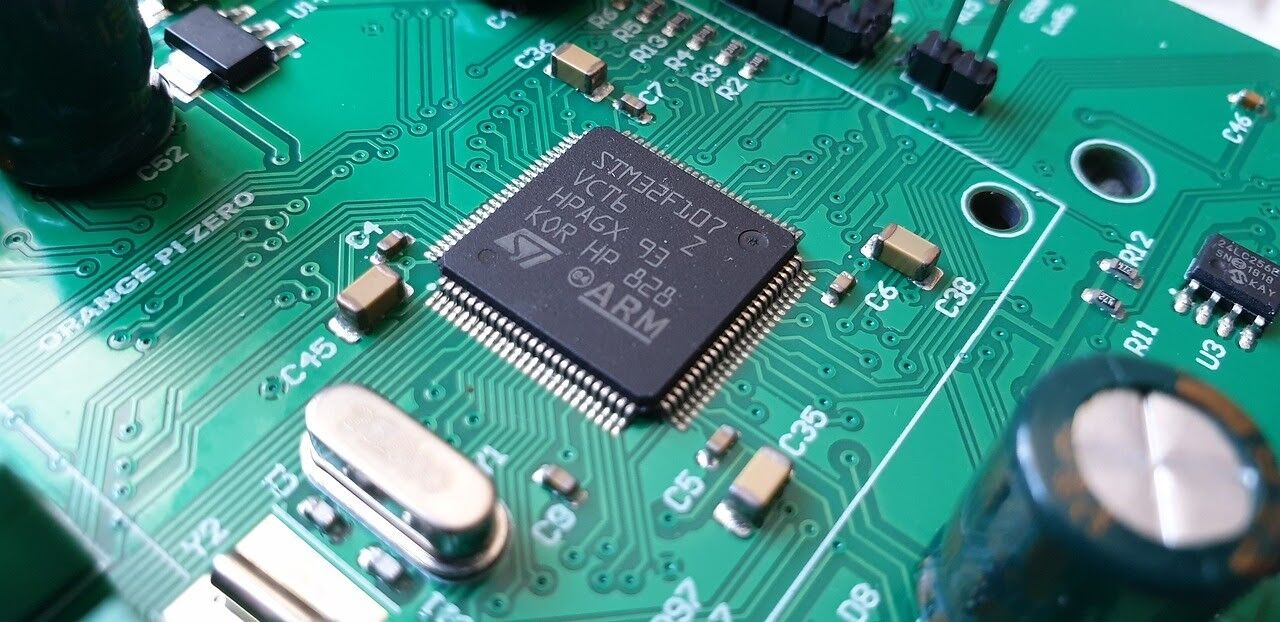

- IPC-A-600: It is vital to get hold of acceptance criteria in tracing nonconforming conditions to their origins in manufacturing process. Following accredited courses not only provide training to personnel involved in the PCB fabrication process but also help acquire stamps of quality to the PCB manufacturing company they are working in.

- IPC-6012: This training course is a comprehensive program that teaches the requirements for design, fabrication, and inspection of unyielding printed boards. The IPC 6012 is a standard that went ahead to establish and define the performance and qualification of requirements for the HDI, and passive/active PCBs.

- IPC J-STD-001 SPACE ADDENDUM: The Space Addendum sets the requirements for specific products with soldered electrical and electronic assemblies that must survive rigorous vibration and thermal cyclic environments for operating in space and military application.

- IPC/WHMA-A-620 SPACE ADDENDUM TRAINER COURSE: This course accommodates actual cable building exercises and concludes with a qualifying examination. Certified Instructors are then qualified to conduct Certified IPC Specialist (CIS) training. Following training include soldering, cup terminals, crimping, machine contacts, insulated lugs, IDC connections, wire splices, coax connectors, shield terminations, including routing using ty-raps/lacing cord, shielding–braid and shrink-tubing, and testing of the final product.

- IPC-WHMA-A-620 CERTIFIED HANDS-ON: A certification for the IPC/WHMA-A-620 Certified IPC Trainer (CIT) signifies your commitment to fulfil customer requirements and capability to adopt and implement ISO and other quality standards. Professionals with this certification gain recognition and value in the entire electronics industry.

Contact Advanced Rework Technology Today

If you currently do not have globally recognized IPC certification in your institute or on your resume and you want to make that superior change, contact Advanced Rework Technology (A.R.T.) today. A.R.T Ltd also offers bespoke training that can be based entirely around the requirement of your company and even specific products, with all theory and practical equipment supplied by them too. All is just a call away from you. Call A.R.T. Ltd today on 01245 237 083.