Electronic components in the future will be smaller, more powerful and more efficient. The higher energy density will translate to increased operating temperatures and more heat. In order to operate these new devices and maintain their performance over their lifetime, advanced thermal management solutions are necessary.

Techsil has launched SilCool* TIA241GF silicone gap filler from Momentive. It is an excellent candidate for applications where good heat transfer, low stress, and good interface wetting are required. This product offers tacky adhesion for applications where movements in x, y, and z directions occur due to vibration, thermal cycling stress and CTE (coefficient of thermal expansion) mismatch.

Techsil has launched SilCool* TIA241GF silicone gap filler from Momentive. It is an excellent candidate for applications where good heat transfer, low stress, and good interface wetting are required. This product offers tacky adhesion for applications where movements in x, y, and z directions occur due to vibration, thermal cycling stress and CTE (coefficient of thermal expansion) mismatch.

SilCool* TIA241GF gap filler has demonstrated superior performance in terms of reliability, adhesion, and thermal resistance over competing materials. This material was initially proposed for automotive applications (e.g. automotive electronic control units and systems) but can also be used as a thermal interface for electronic components in automotive, consumer, telecommunication, lighting and industrial devices.

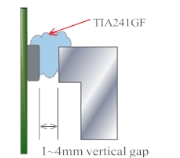

This thermal gap filler is a 2-part, soft, thermally conductive silicone material. Its non-slumping pasty consistency offers physical stability for optimized processing. TIA241GF can be used as liquid dispensed alternative to pre-fabricated thermal pads, for a broad array of thermal designs in electronic applications.

KEY FEATURES AND TYPICAL BENEFITS

-

Good thermal conductivity 4.1 W/mK

-

Fast, low temperature cure

-

Convenient 1:1 mix ratio by weight

-

Retained softness after cure to contribute to stress relief during thermal cycling

-

Excellent slump resistance (stays in place)

-

Repairability

-

Flame retardantcy: UL94V-0 equivalent

-

Glass bead option availability (180 & 250µ) for bond line thickness (BLT) control

Glass bead option availability (180 & 250µ) for bond line thickness (BLT) control -

Long-term reliability and exceptional performance

-

Consistent filling of multiple thickness gaps under one common heat sink

-

Excellent surface wetting

-

Excellent for maintaining contact through thermal cycling

This new liquid-dispensed gap filler will further strengthen Techsil’s existing thermal management range. In addition, Techsil hope to expand their liquid dispensed gap filler range with a 5WmK and 8Wmk material in the near future.