In2tec unveils advanced automotive HMI capability with steering wheel innovation

A next generation steering wheel technology demonstrator from In2tec is the culmination of the company’s 20-years+ expertise in Smart HMI electronics gained from working within the automotive and aerospace industries. The company is focused on developing sustainable electronics, which has been a key consideration during the design cycle of the steering wheel demonstrator.

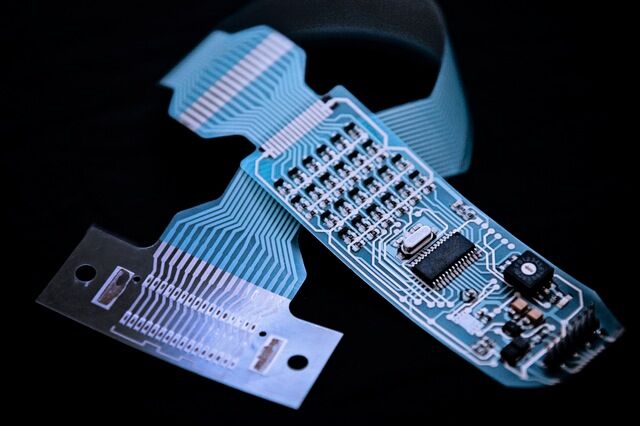

A fusion of the company’s sustainable flexi-hybrid technology and highly recyclable electronic assemblies, the low-profile steering wheel utilises advanced and patented flexible electronics that address function, aesthetic, and packaging constraints, to showcase ground-breaking possibilities in vehicle control systems.

Neil Armstrong, Group Managing Director, In2tec, says: “Using the latest in Smart HMI, touch technologies, and 3D conformable circuit boards, we have developed a flexible electronics solution that will transform the future of automotive manufacture and design. The In2tec technology demonstrator enables us to share what this next-level system capability can offer OEM and Tier 1 suppliers. Crucially, it also encompasses highly recyclable electronic assemblies thanks to our flexi-hybrid technology and low carbon footprint recycling processes.”

The design utilises existing capabilities like capsense with the integration of Hands-Off-Detection (HOD)/ Hands-On-Detection functionality and dynamic monitoring of the heart rate, which futureproofs the wheel’s capabilities in line with existing and next-generation safety and legislation requirements.

In2tec’s flexi-hybrid technologies work seamlessly with interface solutions like proximity detection and haptic technologies enhancing the ergonomic profile of the design and ultimately elevating the user experience.

Integrating an ultra-thin complex curve construction built around flexible electronic circuit assemblies, the wheel’s profile incorporates concave and convex surfacing not achievable with rigid or semi-rigid printed circuit technologies, such as those found in current standard technologies. Moreover, In2tec’s flexible electronic assemblies allow a more free-form approach to the shape of the whole wheel. So, the complex 3D shapes allow for sensors, and the user interface to seamlessly fit within the complex and limited space within the steering wheel’s assembly, helping reduce both footprint and weight.

The low-profile OLED hi-definition LCD display is contoured, to provide an ergonomic and immersive experience that allows details to be clearly displayed to the driver. The ‘always up’ LCD display ensures information remains vertical for ease of use in real-world driving conditions even when the wheel is turned.

Both vehicle and driver data can be displayed as it can collate and present information like grip-slip and G-force, with the driver’s heart rate and pulse trace information that are gathered through the sensors built into the steering wheel. The driver awareness function enabled through inbuilt micro cameras provides the hub for driver safety management systems as well as driver-vehicle setting preferences linked to driver recognition. Automatic driver recognition technology sets driver preferences and monitors behaviour and attentiveness whilst driving.

There’s even space for an LED lighting guide along the top portion of the wheel to safely communicate the vehicle’s functional state in the driver’s peripheral vision. This innovative light bar is a ‘Secret-til-Lit’ feature, which provides visual feedback only when needed, and so minimises driver distraction. It communicates rev limits, over-speed warnings, left/right vehicle indicator alerts via diffused ambient light, with output through an array of individually addressable RGBW LEDs. Positioned at the top of the wheel the LED light bar is strategically located to provide critical visual safety alerts for driver awareness including driver Hands-On/Hands-Off status.

The use of capsense buttons with proximity detectors allows illumination by half-light when the driver’s hand hovers over them, until which, the buttons are only visible by their surface profile. Capsense technology enables the buttons’ graphics to fully illuminate driver information on contact, only when needed. This simplifies the layout of the wheel minimising driver distraction.

A further feature includes the integration of ultra-thin e-paper graphical displays on the gear and clutch shift paddles, which provide operational status information on current gear selection, and indicates the need to change gear. The low energy e-paper has the benefit of retaining the displayed image, even when no power is applied. These are integrated using robust connections provided by In2tec’s patented flat shielded twisted pair communications technology.

The wheel also includes a vehicle start-stop capacitive slider function and integrated ultra-low profile thumbwheel technology for easy access to the menu and infotainment options.

Dr. Mark Hudman, Development and Engineering Director, In2tec, says: “In2tec has a strong history of delivering innovation to the automotive industry. We want to push the boundaries further by redefining the driver experience while building on the latest in connectivity, safety, security, and sustainability.”

He added, “Our innovative sustainable flexible electronics solutions have allowed In2tec to move beyond what is currently achievable in automotive design with traditional methods. This innovative, Smart HMI steering wheel technology demonstrator shows the incredible possibilities for engineers and designers, using our advanced and patented electronics for design, functionality, and style. Our highly recyclable flexible and flexi-hybrid electronics technologies include our commitment to providing materials, design models, and manufacturing methodologies that allow a truly circular economy and a positive impact towards achieving Net Zero Carbon Emissions.

ReUSE provides substrates, circuit tracks, and component bonding systems that can be fully unzipped using organic solvents, significantly reducing the energy and high costs of manufacturing and recycling.”

British-based In2tec Ltd specialises in the design and manufacture of sustainable flexible electronics and Smart HMI solutions for a broad range of applications that extends across all sectors. This technology demonstrator shows the opportunities for automotive designers of in-vehicle electronic interfaces, but moreover it showcase what In2tec’s unique capabilities and innovative sustainable flexi-hybrid technologies can offer any application for HMI.

With R&D facilities based in the UK and manufacturing centres in the UK and China, the firm delivers innovative custom solutions from simple projects through to the most demanding specifications. Established in 2001 following a management buy-out, In2tec is headquartered in Kettering, Northamptonshire.

In2tec

www.in2tec.com