Non-contact laser displacement sensors from Micro-Epsilon UK have performed flawlessly in on-vehicle ride height tests for the BLOODHOUND SSC Project.

Non-contact laser displacement sensors from Micro-Epsilon UK have performed flawlessly in on-vehicle ride height tests for the BLOODHOUND SSC Project.

The tests, which took place on 11th February 2015, are part of the BLOODHOUND SSC Project – the 1,000 mph land speed record attempt that is scheduled to take place in 2016. The tests were carried out at the Jaguar Land Rover Gaydon Centre in Warwickshire. The Centre houses a design, research and development centre, as well as extensive test track facilities and is used for the design and development of Jaguar and Land Rover vehicles.

As Joshua Thompson, systems engineer at BLOODHOUND Programme and Sargent in the Royal Electrical & Mechanical Engineers stated: “Measuring the ride height is a critical measurement parameter on the BLOODHOUND Supersonic Car. We need to know the exact distance between the wheels and the ground to see how far into the ground the wheels sink during trials.”

Mounted to the chassis of a Jaguar XF test vehicle with the laser window pointing down towards the ground, the optoNCDT 1700 high speed sensor accurately measures and monitors the ride height of the car. The sensor will enable the BLOODHOUND SSC team to adjust the suspension characteristics in order to optimise the performance of the car.

The objectives of the ride height tests at Jaguar were twofold. As Joshua Thompson explained: “First, we needed to test the performance of the ride height sensors under harsh, on-vehicle conditions. We also wanted to verify that our software could correctly interpret the measurement data coming from the sensors. On both counts, the tests were successful.”

For the ride height tests, two optoNCDT 1700 laser displacement sensors were mounted side-by-side to an adapted tow bar at the rear of the Jaguar XF. “We wanted to compare the measurement data coming from the two sensors, which were set up at a measuring range of 300mm from the ground [the midrange of the sensor] to measure the ride height of the car. In the record attempt itself, one ride height sensor will be mounted to each of the four wheels on the car,” added Thompson.

Flawless performance

During the tests, the car was accelerated up to a maximum of 50mph, as the off-road conditions were too muddy and bumpy for higher speeds to be reached. However, as Thompson states, “the two optoNCDT 1700 sensors performed flawlessly during the tests. They captured the data we required and there were no discrepancies between the two sensors in terms of the analogue output data they provided.”

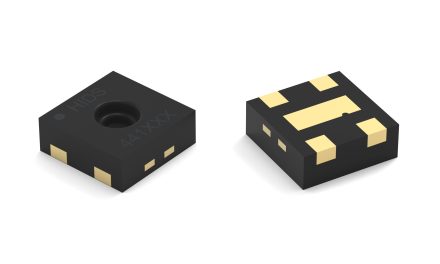

The optoNCDT 1700 series of laser displacement sensors provides multi-functional features. The unique Real Time Surface Compensation (RTSC) feature enables measurement against a wide range of material surfaces. The sensor’s unique compact design (and integrated conditioning electronics) makes it ideal for a variety of industrial applications in R&D, testing, automation and OEM production systems. Measuring ranges are from 2mm up to 750mm. Maximum linearity is 2µm and maximum resolution is 0.1µm. Measuring rates are configurable up to 2.5kHz and a freely programmable limit switch is also provided.

As well as on-vehicle testing, Micro-Epsilon’s optoNCDT 1700 series of laser displacement sensors will also be used for the BLOODHOUND SSC record attempt itself. In addition to ride height sensors, Micro-Epsilon is also providing sensors to BLOODHOUND Programme Limited that will be used throughout the testing, production and operational stages. These sensors include non-contact temperature sensors, thermal imagers and non-contact capacitive displacement sensors.