Mark Stephenson at KOE Europe explores the evolution of industrial LCDs and how the user interface is shaping performance expectations

Mark Stephenson at KOE Europe explores the evolution of industrial LCDs and how the user interface is shaping performance expectations

Industrial LCDs are evolving and increasing in number. But what is an industrial LCD? Display manufacturers are primarily driven to design and develop displays for high volume OEM markets and applications such as smart phones, tablets, portable media devices, personal navigation devices, automotive, monitors and TVs.

The production volumes associated with these high volume markets drive display development and the adoption and implementation of new technologies and techniques. The displays and technologies used in these market sectors can therefore often be seen as providing the precursors for the next generation of industrial displays.

This, however, does not preclude the development of some displays specifically for the industrial market. Design engineers need to ensure that the industrial LCD of choice provides excellent optical performance, that it is inherently reliable and perhaps most importantly, that continuity of supply can be maintained during the product lifetime.

True industrial environments can create unique demands for displays used in electronic systems and equipment. A typical industrial environment may present challenges such as high ambient light, temperature extremes and mechanical shock and vibration. Industrial LCDs do however adhere to some defined standards and formats. Typically, four key characteristics influence the design and usage of the display: optical, mechanical, electrical and environmental.

Graphical user interfaces need to be capable of displaying bright, vivid display images and information.

Demand for wide viewing angle and wide field of vision displays have increased in many embedded and industrial systems. Many user interfaces require highly consistent optical performance and image representation.

Contrast and colour uniformity must be maintained over a wide range of viewing angles and positions. When viewed from an acute angle, some TFT displays can exhibit a loss of brightness that results in a reduction in contrast and the display image becoming inverted.

Adding sophisticated capabilities

Wide viewing angle technologies such as in-plane switching (IPS) and vertical alignment (VA) are now extensively used by blue chip companies in the manufacture of high performance smart phones, tablets, monitors and flat screen televisions.

IPS and VA TFT display modules overcome the limitations of conventional TFT display technology by providing a stable colour image from any viewing angle (up to 176° in both vertical and horizontal planes), excellent colour saturation, colour stability and high contrast ratios. Industrial markets can now also benefit from these key features as industrial specification IPS displays become more widely available.

The use of industrial specification IPS displays offers an effective cost versus performance display when compared with traditional TN (twisted nematic) TFT modules. IPS displays offer exceptional colour saturation with very high contrast ratios: enhanced black levels combined with improved transmittance enable contrast ratios of up to 1000:1.

Robust, reliable and power efficient LED backlights have replaced cold cathode fluorescent lamp (CCFL) backlights in industrial LCD modules.

Some industrial LCDs also feature integrated LED controllers enabling 100 to 0 percent backlight dimming whereas CCFL backlight dimming was typically only possible to 50 percent.

LED lifetime characteristics are important with lifetime estimations of between 70k and 100k hours being quoted by display manufacturers.

The lifetime of LED backlights is less affected by variations in operating temperature, which in an extreme industrial environment is essential for ensuring a reliable, maintenance free display installation.

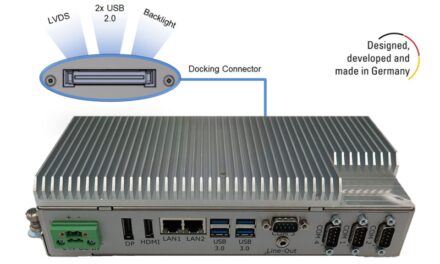

There are two industry standards for the electrical interface used on many industrial LCDs: RGB CMOS and LVDS. These two data interfaces can be implemented to use either 6-bit or 8-bit data, which enable colour palettes of up to 262k and 16.7M colours, respectively.

Integrating a LVDS data interface on an industrial display allows high speed digital transmission of the image data with low power consumption, excellent tolerance to transmission line effects and good noise immunity.

Many industrial applications use highly functional single board computers (SBC) for the core application task, the ability to drive high resolution LCDs and provide LED backlight control. The common implementation of LVDS and the increasing adoption of DisplayPort interfaces on SBC and industrial LCD modules is now becoming mandatory as display resolutions increase and the ability to support remote, distant monitoring is often required.

The very nature of industrial applications suggests that the environment in which a product or system is going to be used will be harsher and more extreme than a typical consumer product. An operator panel on a forklift truck or a navigation panel on a marine craft will almost certainly present a more testing environment than that of a consumer smart phone or tablet.

The specifications and interfaces of industrial LCD modules are continually being optimised for industrial applications, ease of design and integration as display manufacturers recognise the significance of a growing and expansive industrial marketplace.

Continuing developments in traditional TFT technology and the migration of wide viewing angle technologies to industrial displays allow the product designer to chose a display from an expanding portfolio of high performance industrial TFT displays.

KOE Europe