Modern production centre and business location will increase efficiency and capacity at hi-rel connector and PCB hardware company

Harwin has broken ground on a major new extension at its Portsmouth headquarters and manufacturing centre. The new building will increase floor space by 33%, which will be dedicated to increased automation and R&D facilities.

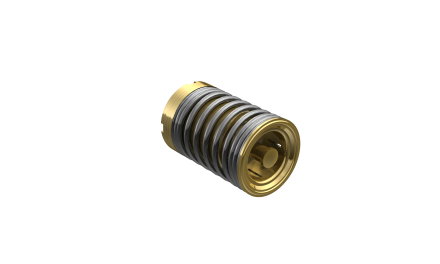

The extension of the site has been driven by Harwin’s strong success in recent years and projected growth forecasts. It is part of the company’s philosophy to keep all key manufacturing process – stamping, plating, moulding, turning, assembly and tool making – in house in order to ensure quality and support new product innovation, and the company implements a strict policy of replacing its plant and equipment on a 5-year cycle. The company’s success has meant that the existing facility is close to capacity, hence the £2M investment in new buildings and equipment. Already, Harwin has taken possession of two Tornos Nano sliding head turning centres which will increase manufacturing output and reduce waste.

Comments Chairman Damon de Laszlo: “We expect the new construction to be fully facilitated and in use by March 2016. We are taking the opportunity to streamline our manufacturing operations so we expect significant efficiencies to be made as well as the increase in capacity. And we are looking to be as environmentally-friendly as possible too – the roof of the new premises will be covered with solar panels which will produce much of the energy we use.”