Roberta Rebora, Marketing Director at Hypertac Europe, explores the latest technology options for supporting the growing trends in miniature, safer and lighter weight interconnect solutions within the rail industry

Roberta Rebora, Marketing Director at Hypertac Europe, explores the latest technology options for supporting the growing trends in miniature, safer and lighter weight interconnect solutions within the rail industry

The unique nature of rail traction and infrastructure applications put extreme demands on interconnection technology manufacturers. In addition to the more traditional driving forces, engineers are also subject to extreme application and environment specific requirements.

The demand for innovative interconnect solutions incorporating power, signal and optical technologies has increased significantly, resulting in the need to develop much smaller yet higher-density connectors with improved transmission speeds and energy transmission efficiencies.

The reduced connector size is lighter in weight and allows the equipment designer more space for other electronic components within the system.

Solutions available on the market today offer modern technology in response to market demand, such as Hypertac’s connector platform for the Eurobalise system. The company initially designed the original bayonet lock BOA connector; a heavy-duty transponder for the Eurobalise system, incorporated within train communication systems throughout Europe.

This technology is located at regular intervals within the rail tracks; balises are an integral part of the European Train Control System, where they serve as ‘beacons’ giving the exact location of a train.

A system of great integrity

The function of the Eurobalise is to transmit a message to the train borne equipment to provide the driver and the on-board ATP processing unit, information about the current train position and the conditions of the track and traffic ahead.

This allows appropriate action to be taken regarding train speed and progression, ensuring the safety of passengers throughout the network. The BOA connector allows high-speed data transmission with excellent signal integrity and very low bit error rates.

The use of special alloys and conductive plating finishes ensure the connector’s resistance to the harsh environmental conditions, which are encountered along railway tracks.

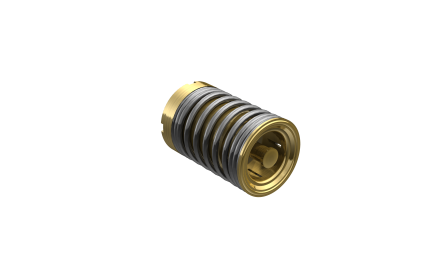

In succession to the BOA connector, the company has introduced a new generation of mini-Balise circular connectors to accommodate the required changes defined within the updated Eurobalise system.

The new ‘Mini Boa’ connectors are specifically designed to meet the compact size and improved electrical and environmental requirements identified within the new specification.

The new system solution allows co-moulding of the metallic body of the empty receptacle onto the plastic body of the ‘Mini-balise’. The connector insulator equipped with signal contacts can then be inserted into the receptacle/body assembly in a much more cost-effective secondary process.

A significant environmental improvement is the new non-reflective black plating finish (black Cataphoresis) applied to the exposed connector metallic parts, which provides a salt fog resistance of 500 hours.

For such a safety critical piece of equipment, the connector also ensures reliable signal integrity and transmission of data between the rail track and the train borne equipment, vital for the high-performance Eurobalise system.

The new range of balise connectors is specifically developed in partnership with a major European rail-signalling specialist, to integrate seamlessly with the customer’s overall system and to meet with European Standard requirements.

The new platform has also been designed for use with the ASFA system (Anuncio de Señales y Frenado Automático), a signal repeater system with train control functions based on data transmission from the Balise to the train-borne equipment.

The new range of 13 way circular connectors use anti-tampering screws that are designed to prevent any unauthorised external intervention.

Depending on, which male connector the operator plugs into the receptacle, the system changes its functionality so different colours can be closely associated to different functions.

The connectors are IP 67 rated according to IEC 529 when mated with a counterpart and have been tested for salt-water mist. A 21 way version equipped with the company’s new contact technology is available for applications, which require an even higher density of connections.

Hypertac Europe

www.hypertac.com