Manufacturers increasingly need to consider their products from the perspective of how happy the consumer is with their purchase. Negative reviews by customers on online sites can have a catastrophic impact on sales. 88 per cent of consumers now state website ratings and reviews as their primary source of information when considering the purchase of a product. To retain competitive advantage, therefore, manufacturers need to ensure their customers are happy.

Manufacturers increasingly need to consider their products from the perspective of how happy the consumer is with their purchase. Negative reviews by customers on online sites can have a catastrophic impact on sales. 88 per cent of consumers now state website ratings and reviews as their primary source of information when considering the purchase of a product. To retain competitive advantage, therefore, manufacturers need to ensure their customers are happy.

The key to having happy consumers is understanding their expectations and then either matching or exceeding them. Usability is a large part of those expectations. Usage assessment has become one of the most important tools available to a manufacturer when helping them define and anticipate user’s feedback.

Products must also be ‘fit-for-use’. A ‘fitness-for-use’ assessment identifies possible weaknesses and allows manufacturers to compare their products with their competitors. This allows a manufacturer or supplier to position their product in the right, competitive environment. It will also mitigate some of the risk associated with negative feedback.

‘Fitness-for-use’ assessments match the prime areas of usage that are commented on by consumers. These include:

- Instructions to user

- Handling

- Performance

- Durability

- Usage

Negative reviews in any of these areas can mean a drop in future sales.

Which protocols need to be applied to the product to exorcise them of any negativity will, of course, rely on the type of product. With electrical and electronic equipment (EEE) products, a variety of testing protocols have been developed by SGS to help manufacturers and suppliers monitor and rate their products. These include:

- Power tools – drills, grinders, etc.

- Garden tools – lawnmowers, chainsaws, hedge trimmers, etc.

- Household appliances – steam irons, coffee makers, hair dryers, etc.

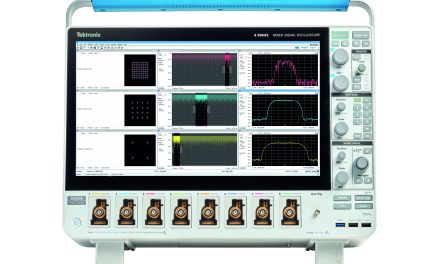

- Audio/video products

The starting point for any testing protocol is the perspective of the user. Performance certification can also be used by manufacturers and suppliers to help differentiate their product in the marketplace. Following testing, the certification can be displayed on packaging, thereby demonstrating to consumers that the declared characteristics have been thoroughly tested and validated.

SGS performance services

SGS offers a comprehensive range of ‘fitness-for-use’ testing services at its high-tech facility in Aix-en-Provence, France. They can conduct both performance and endurance tests, which can be replicated exactly to allow accurate comparisons between models.

These tests can also be used to identify weaknesses, allowing timely rectification, in addition to mitigating against negative reviews. For example, user guides can be modified, or parts and components can be replaced, if the tests reveal a problem. SGS can also support manufacturers during the rectification work, helping them to understand the test results and provide suggestions for improvement.

For more information on these services, click here.